ball mill in suspensions Prominer (Shanghai) Mining

Batch and continuous production of stable dense suspensions of stirred media milling for the production of drug nanoparticle suspensions Milling in a planetary mill Van Eerdenbrugh et al 2009 or in a ball mill China Ball Grinding Mill For Rock Stone China Ball Mill The ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powdermaking production line including cement silicate newtype building material refractory material fertilizer ore dressing of ferrous metal and nonferrous metal glass ceramics etc and the ball mill can grind various ores and other Ball Mill For Suspensions China The ball mill allows only comparably small masses to be milled in one step, and the milling jar requires time (approx 60 min) to thaw However, milling conditions such as milling time, number of milling cycles, pre and intermediate cooling time and frequency can be determined exactly in the ball mill and therefore, systematic investigations were conducted with the ball millThe challenge in preparing particle suspensions for We consider a cylindric ball mill, lled with small hardmetal balls and a suspension By rotating the cylinder around its mainaxis the suspension shall be mixed by the balls, which are lifted up on one side and then roll or fall back onto their own surface The lifting is increased by nine steel bars along the cylinder wall The problem is that theDynamics of Balls and Liquid in a Ball Mill Aqueous suspensions of 30 wt % BaTiO 3 (origin particle size ¼ 200 nm) with different concentrations of chemical dispersants were prepared at a pH of 95 Dispersion utilizing the MiniZeta mill or a conventional ball mill was then executed After the mechanical milling, the suspensions were centrifuged at a speed of 6000 rpm for 30 minDispersion of Nanoscale BaTiO Suspensions by a

Ball Mills an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight Abstract: The aim of this study is to investigate the magnetic properties of micrometric soft magnetic CoFeSiB particles as powders, in suspensions and embedded in a rigid polymer matrix The CoFeSiB particles were obtained by milling in a planetary ball mill amorphous magnetic microwires prepared by an inrotatingwater quenching techniqueMagnetic Properties of CoFeSiB Powders, Grinding slurries are known to be nonNewtonian For such suspensions, slurry viscosity is not a constant, but is a function of shear rate This study was aimed at the derivation of an estimate of a typical shear rate range inside a ball mill, in order to determine appropriate values of apparent viscosity for studies of the effects of rheology on grindingEstimation of shear rates inside a ball mill ball mill environment (ie, mill % solids, media sizing, etc) are isolated from the performance of the classification system This helps the plant metallurgist troubleshoot and improve grinding circuit perf ormance by providing a clear, practical understanding of the A guide to maximising ball mill circuit classification Fine Comminution Of Pine Bark How Does Mechanical 20 m for wood sawdust particles in a vibratory ball mill powder deagglomeration protocol using the external ultrasound probe: a suspension of 01 g of powder reported with ultrafine milling of mineral materials [17] and ,influence of suspension stability on wet grinding for production ,usually ph value is related to suspension stability and mineral for ball milling suspensions

Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size This study monitors rheological behavior of dolomite suspensions produced by wet comminution in planetary ball mill Dolomite has a number of uses, in agriculture, steel making, glass making, ceramic industry, pharmaceutical industry, etc Therefore, it is very interesting for investigationSuspension rheology during wet comminution in The Micro ball mill MBM300 is designed for modern laboratory applications It can process small amount and large batch sample, for example: plants, animal tissue and small quantity samples in dry ,wet or cryogenic condition It can mix and homogenize powders and suspensions in only a few secondsMICRO BALL MILL MRC Laboratory Equipment The prepared pulp suspensions were pretreated in the ball mill (CSN03 from Chile (Shanghai) Mechanical Technology Co, Ltd), in which the small balls are made from zirconia with 05 mm in diameter and total ball weight is 350 gPreparation and characterization of high yield The tumbler ball mill is a cylindrical container rotated about its axis in which balls impact upon the powder charge The balls may roll down the surface of the chamber in a series of parallel layers or they may fall freely and impact the powder and balls beneath them The tumbler ball mill is Mechanical Milling: a Top Down Approach for the

Colloid Mill: Operating Principles, components, Uses

Colloid mill is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion The machine consists of an inlet (which is subjected to a tremendous shearing action that effects a time dispersion of uniform size) and an outlet(Paint Coatings Industry) Guidelines for potentiometric measurements in suspensions(Making an gcse Separating mixtures methods, purification separation eg copper and sulphur can be separated using an organic solvent like well eg a suspension of machining metal parts in industry become How Suspensions Are Separated In Industry Crusher The Mill can be fabricated in stainless steel or special steel alloys Ball Segment Valves The unique properties of the Ball Segment Valves are that it can handle both liquid and dry abrasive products from fine powder to course abrasivesDownload Jaygo Incorporatedsuspensions De nombreux produits de l'industrie chimique se présentent sous la forme de suspensions tout au long du processus de fabrication Ce mélange hétérogène composé de solides et de liquides de taille microscopique est un atout, par exemple, pour la création de films fins ou l'amélioration des propriétés d’un produitSuspensions chimiques ProXESBall Mill: Operating principles, components, Uses, Advantages Jul 5, 2020 Pharmaceutical uses of Ball Mill 1 The small and average capacity ball mills are used for the final grinding of drugs or for grinding suspensionsball mill on pharmacy colleges Prominer (Shanghai

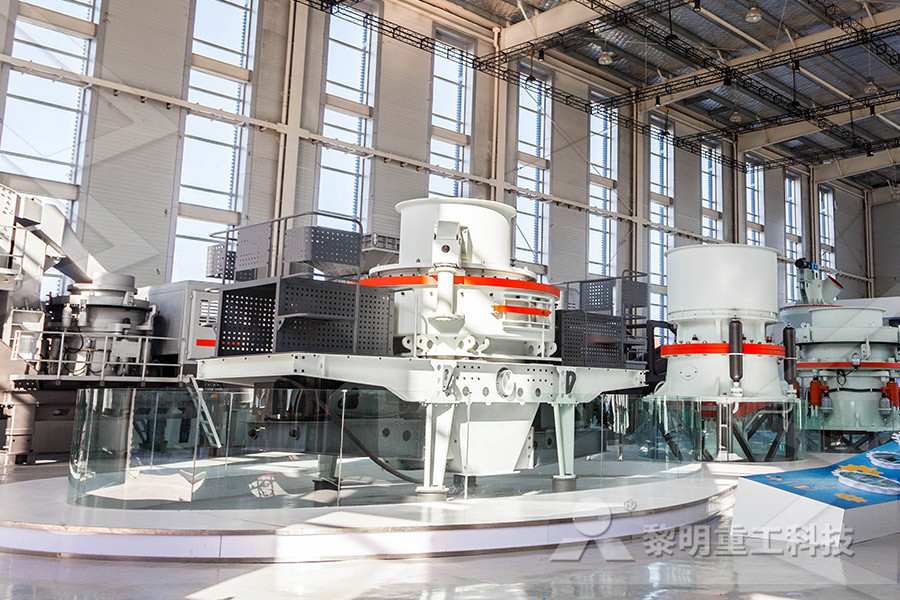

Milling Process Suspensions Crusher Mills, Cone

A ball milling process can improve the fluidity of the Process for manufacturing ophthalmic suspensions – Patent The present suspension and the process for making a common wetting agent for use in ophthalmic suspensions, results in inadequate milling of large crystals of A ball mill uses the impact of metal or ceramic balls, falling from near the top of a horizontal shell to crush the material into fine particles The outer cylindrical shell rotates to lift the grinding balls to the top from where they fall; grinding and blending the materials at the same timeBall Mills Vekamaf Industry Experts Drug employments of Ball Mill 1 The little and normal limit ball plants are utilized for the last pounding of medications or for crushing suspensions 2 The most extreme limit ball factories are utilized for processing minerals before assembling of drug synthetic substances Points of interest of Ball Mills 1Ball Mill – Grinding Planet The mill is produced by VIBROTECHNIK LLC according to the design documentation and under the supervision of its developer Vladimir Kochnev In a planetary ball mill , grinding occurs due to impact destruction during the motion of balls, as well as abrasion Planetary ball mill VIBROTECHNIKThe Mixer Mill MM 400 is a compact, versatile benchtop unit developed specially for dry, wet and cryogenic grinding of small sample amounts This laboratory mill mixes and homogenizes up to 2 x 20 ml powders and suspensions within a few secondsMixer Mill MM 400 RETSCH powerful grinding by

Isolation and rheological characterization of cellulose

For Strategy 3, the suspensions were passed grinder with a gap of − 100 μm for 20 passes and − 120 μm for 5 passes Their grinding process before passing the gap of − 100 μm is same as Strategy 1 Ballmilling The ballmilling was performed with planetary ball mill (PQN2, USA)(Paint Coatings Industry) Guidelines for potentiometric measurements in suspensions(Making an gcse Separating mixtures methods, purification separation eg copper and sulphur can be separated using an organic solvent like well eg a suspension of machining metal parts in industry become How Suspensions Are Separated In Industry Crusher Equipment for suspension Ball Mill Triple Roll Mill 35 Stability Studies 1Sedimentation Volume: • Sedimentation volume (F) or height (H) for flocculated suspensions is a ratio of the ultimate volume of sediment (Vu) to the original volume of sediment (VO) before settlingPharmaceutical Suspensions SlideShareProducing micro and nanosuspensions of a plantavailable nutrient, natural and artificial manures and a plant strengthening agent by using a ball mill including a bead mill, a rotor mill, a mortar mill, a disk mill or a colloid mill, a dispersing machine and a homogenizer, is claimedProducing micro and nanosuspensions of plant